Improve workability through lower concrete temperature for easier finishing and improved slump life.

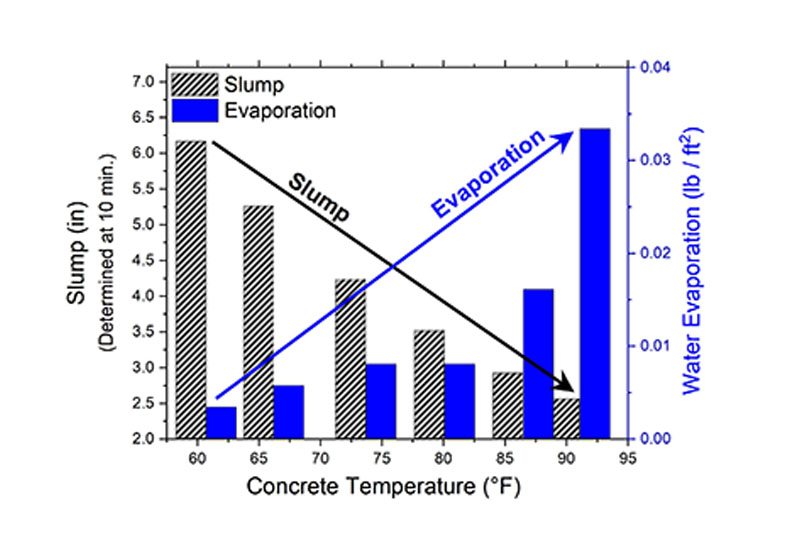

Most people in the concrete industry know that higher concrete temperatures lead to reduced finishability, lower slump, and increased effort for a quality surface finish. Low temperature improves workability and slump retention, according to research from the Portland Cement Association (PCA)1. This research is born out in the field with projects achieving easier workability when customers employ NITROcrete™ temperature control in production.

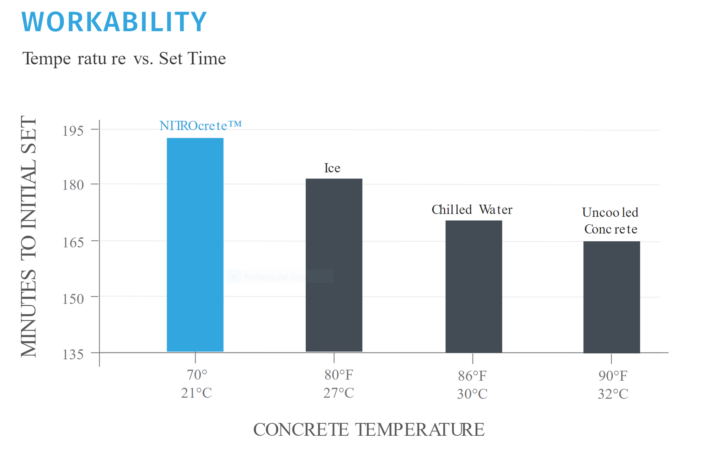

Temperature vs. Set Time

NITROcrete™ Research & Development used baseline research for comparison. These data show a relationship between set time and temperature. The chart below compares NITROcrete™, ice, chilled water, and uncooled concrete. In field tests, NTIROcrete™ allows the greatest set time.

With lower temperature, the duration of set time increases, making concrete easier to work with for longer. Better workability also makes a higher quality surface finish easier to accomplish with less strain on labor.

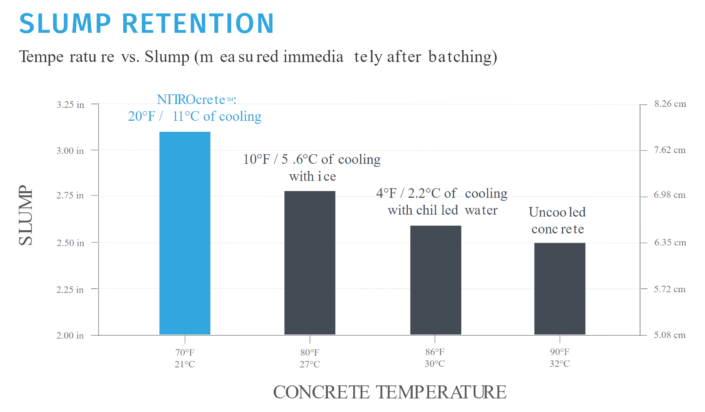

Temperature vs. Slump Retention

Controlling temperature, which affects slump retention, leads to concrete that performs better with more cost-effective cooling than ice, chillers, or other methods.

The chart data below, also sourced from the Portland Cement Association, compares slump with concrete temperature. The measurements for slump were taken immediately after batching.

Conclusion

Lab and field testing show the correlation between lower temperature and concrete that is easier to work with and easier to place. Improved workability and directionally longer slump life result in reduced labor effort and time.

References

1 Burg, R., Portland Cement Association Research and Development Bulletin RD113T, 1996

Chart data source: ibid.

Last updated: September 9, 2020 at 11:15 AM MST

Due to continued product research and development, the information herein is subject to change without notification. Details of this Technical Sheet are believed to be accurate at time of publication.

About NITROcrete™

NITROcrete is the world leader in concrete temperature control. In 2012, what started as a jobsite problem for a partner evolved into a product that is revolutionizing the concrete industry. The team listened, tested, developed prototypes, and made adjustments. Then they listened more, tested more, and in 2017, after 5 years of R&D, they introduced NITROcrete, a comprehensive concrete solution born directly out of the concrete industry.

The largest concrete companies in the world now use NITROcrete to simplify their processes, streamline their operations, and grow their bottom lines. NITROcrete provides a comprehensive concrete solution–cooling, system management, and support–which gives its worldwide industry partners unmatched efficiency, control, and peace of mind.

Advantages

- Improve Set Time

- Better workability, easier finishing

- Higher quality surface finish

- Cost-effective cooling

Documents

- add documents

Additional Technical Summaries

Workability, Evaporation, and Concrete Temperature | NITROcrete

Reduce Carbon Emissions and Waste

Stabilize Hydration Rate

Reduce Plastic Shrinkage Cracking