Workers report concrete cooling they could feel through their boots.

Sweltering summer heat in Atlanta, Georgia is not where you’d expect to hear teammates say “my boots are actually cool right now” while finishing concrete. Yet, finishers couldn’t believe how easy NITROcrete™ was to work with, even with high ambient temperture and low water, high cement content mix design.

Project

- 85° F / 29° C ambient temperature

- 350+ cubic yard PT slab

- High rise luxury residential condos in Atlanta, Georgia, Summer 2020

- Customer: international ready mix producer

Challenge

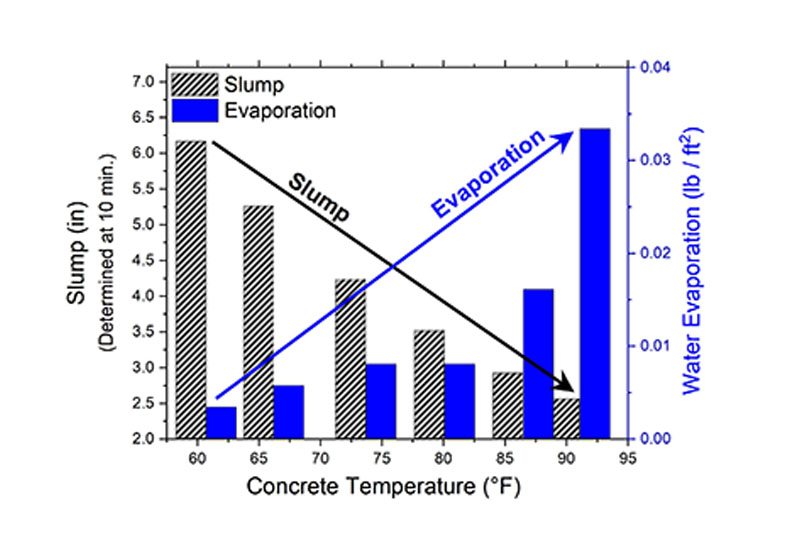

- High ambient temperature during midday pouring in late June

- Project required a high cement, low water content mix

- High rise in a densely populated urban area

- Day began with snags with batching software requiring excellent customer support

Why do customers see these results?

Learn more about the concrete science behind NITROcrete’s technology from the latest R&D updates.

Advantages

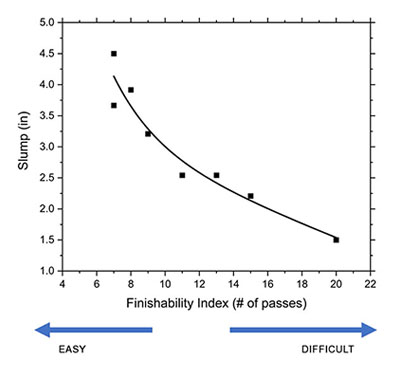

- Improved workability for hot weather concreting

- Concrete cooling provided for low water content, high cement mix without affecting the mix design

About NITROcrete™

NITROcrete is the world leader in concrete temperature control. In 2012, what started as a jobsite problem for a partner evolved into a solution that is revolutionizing the concrete industry. The team listened, tested, developed prototypes, and made adjustments. Then they listened more, tested more, and in 2017, after 5 years of R&D, they introduced NITROcrete, a comprehensive concrete solution born directly out of the concrete industry.

The largest concrete companies in the world now use NITROcrete to simplify their processes, streamline their operations, and grow their bottom lines. NITROcrete provides a comprehensive concrete solution–cooling, system management, and support–which gives its worldwide industry partners unmatched efficiency, control, and peace of mind.